Kicking off with heated oxygen sensor bank 2 sensor 2, this sensor plays a crucial role in your car’s engine health. Understanding how it works, potential problems, and fixes is key to keeping your ride running smoothly. It’s like a tiny detective inside your engine, constantly monitoring oxygen levels to ensure optimal combustion and fuel efficiency. Think of it as a vital cog in the machine, making sure everything’s firing on all cylinders.

This guide dives deep into the heated oxygen sensor bank 2 sensor 2, explaining its function, common issues, diagnosis, repair, and even its environmental impact. From basic descriptions to advanced troubleshooting, we’ve got you covered. Get ready to level up your car knowledge!

Heated Oxygen Sensor Bank 2 Sensor 2 (HO2S Bank 2 Sensor 2)

The Heated Oxygen Sensor (HO2S) Bank 2 Sensor 2 is a crucial component in modern internal combustion engines, playing a critical role in emissions control and engine performance. Proper functioning of this sensor is vital for maintaining optimal fuel-air mixture and reducing harmful exhaust emissions. This detailed description elucidates the sensor’s function, operating principle, physical characteristics, and comparative analysis with other types of oxygen sensors.

Sensor Function and Purpose, Heated oxygen sensor bank 2 sensor 2

The HO2S Bank 2 Sensor 2 monitors the concentration of oxygen in the exhaust stream. This data is used by the engine control module (ECM) to adjust the fuel-air mixture in real-time, ensuring efficient combustion and minimizing harmful emissions. Accurate oxygen measurement is essential for maintaining a stoichiometric air-fuel ratio, which maximizes engine efficiency and minimizes pollutant output.

My car’s heated oxygen sensor bank 2 sensor 2 is acting up, kinda sus. Planning a road trip to the Grand Canyon soon, and figured I’d need to check out the options for a bus to the Grand Canyon from Phoenix. This site seems legit for finding the best deals and schedules. Gotta fix that sensor ASAP, tho, before my trip goes south, ya know?

Operating Principle

The HO2S operates on the principle of measuring the voltage difference between two electrodes within the sensor’s ceramic element. The voltage is influenced by the concentration of oxygen in the exhaust gas. In essence, the sensor measures the electrochemical potential difference created by the oxygen reacting with the sensor’s material. The voltage output varies with the oxygen concentration.

This variation in voltage is interpreted by the ECM to adjust the fuel delivery. The sensor material typically is zirconium dioxide (ZrO 2).

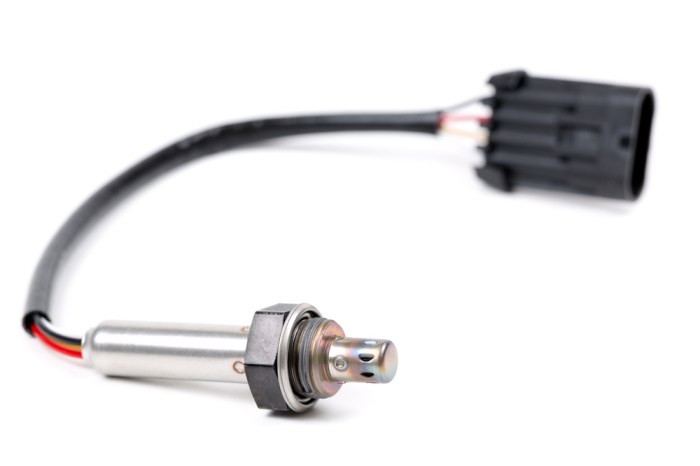

Physical Characteristics

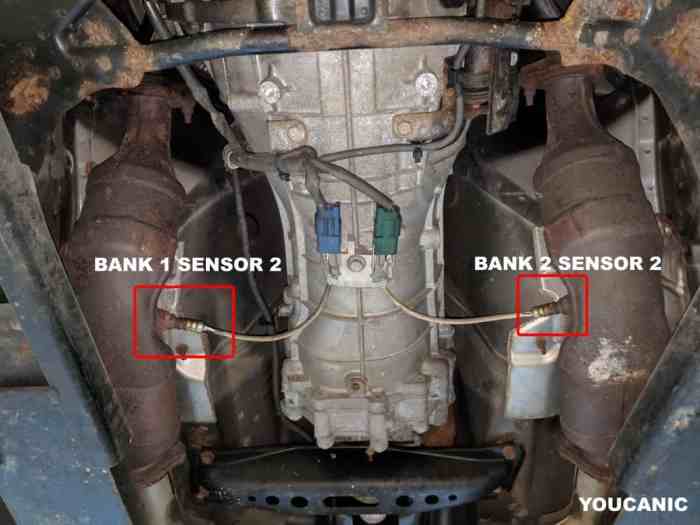

The HO2S Bank 2 Sensor 2 is typically a small, cylindrical device. Its size and shape are tailored for its location within the exhaust system. The sensor’s physical dimensions are crucial for proper fitment and effective operation. Its precise location in the exhaust manifold, often positioned after the catalytic converter, is critical for accurate oxygen readings.

Comparison of Heated Oxygen Sensors

| Sensor Type | Operating Principle | Typical Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Heated Oxygen Sensor (HO2S) | Measures oxygen concentration in exhaust using electrochemical method. Includes a heating element to maintain sensor accuracy at lower temperatures. | Internal combustion engines, particularly those needing precise control over emissions | High accuracy in measuring oxygen concentration over a wider range of operating conditions, especially in cold environments, enabling precise fuel-air ratio adjustments. | More complex design compared to other types of oxygen sensors, potentially leading to higher cost. Requires more power for heating. |

| Non-Heated Oxygen Sensor (Non-HO2S) | Measures oxygen concentration in exhaust using electrochemical method, but does not have a heating element. | Simpler engines, but often in warmer operating conditions. | Simpler design, lower cost. | Accuracy is affected by temperature fluctuations. May not function as effectively at low temperatures. Not suitable for all engine types. |

The table above provides a comparative overview of the key characteristics of heated and non-heated oxygen sensors. Choosing the appropriate sensor type depends on the specific engine requirements, operational conditions, and cost considerations.

Sensor Failure Modes

The Heated Oxygen Sensor (HO2S) Bank 2 Sensor 2 plays a critical role in maintaining optimal engine performance and emissions. Understanding its potential failure modes is essential for accurate diagnosis and effective repair. These failures can manifest in various ways, impacting fuel efficiency, emissions levels, and overall engine functionality.

Common Failure Modes

The HO2S Bank 2 Sensor 2, like other sensors, is susceptible to various failure modes. These often stem from a combination of environmental factors, component degradation, and electrical issues. Faulty wiring, sensor degradation, and external contaminants can all lead to inaccurate readings, which can negatively affect engine performance.

Causes of Failure Modes

Several factors contribute to HO2S Bank 2 Sensor 2 failure. Faulty wiring, such as loose connections or damaged wires, can disrupt the electrical signal sent to the engine control module (ECM). Sensor degradation, often due to high temperatures, exposure to corrosive elements, or extended use, can lead to inaccurate or intermittent readings. External contaminants, like debris or oil, can coat the sensor’s surface, hindering its ability to accurately measure oxygen levels.

Furthermore, manufacturing defects, although less common, can also contribute to sensor failure.

Examples of Sensor Readings Indicating Potential Failure

Sensor readings that deviate significantly from the expected range can indicate a potential failure. For instance, a sensor consistently reading lean conditions, even when the engine load and speed are stable, may suggest a problem. Conversely, a sensor constantly reporting rich conditions can also signal a fault. Furthermore, erratic or fluctuating readings, even within a seemingly acceptable range, can point towards a sensor that is struggling to maintain accurate measurement.

Impact of Sensor Failures on Engine Performance

HO2S Bank 2 Sensor 2 failures can significantly impact engine performance. An inaccurate signal can lead to improper fuel delivery, resulting in either lean or rich air-fuel mixtures. Lean mixtures can cause reduced power output, increased emissions, and potentially damage catalytic converters. Rich mixtures can result in poor fuel economy, increased emissions, and potentially cause engine overheating.

The extent of the performance impact depends on the severity and type of sensor failure.

Potential Symptoms of a Failing Sensor

| Symptom | Possible Cause | Impact on Engine Performance |

|---|---|---|

| Reduced engine power | Lean mixture, inaccurate readings | Reduced acceleration, sluggish response |

| Increased fuel consumption | Rich mixture, inaccurate readings | Lower fuel efficiency |

| Rough idle | Erratic readings, sensor malfunction | Unstable engine operation at low speeds |

| Check Engine Light (CEL) illumination | Sensor malfunction, faulty wiring | Indicates a problem requiring diagnosis |

| Increased emissions | Lean or rich mixture, inaccurate readings | Higher pollution levels |

| Poor acceleration | Lean mixture, inaccurate readings | Difficulty in accelerating the vehicle |

Diagnostic Procedures

Proper diagnosis of Heated Oxygen Sensor Bank 2 Sensor 2 (HO2S Bank 2 Sensor 2) issues is crucial for efficient vehicle repair and optimal engine performance. A systematic approach, utilizing appropriate diagnostic tools and interpreting sensor data accurately, leads to precise identification of the problem. This section details a step-by-step procedure for diagnosing HO2S Bank 2 Sensor 2 malfunctions.Diagnostic procedures for HO2S Bank 2 Sensor 2 involve a systematic approach to isolate the cause of the sensor failure.

The steps Artikeld below, coupled with careful interpretation of sensor data, enable technicians to identify and resolve issues effectively.

Diagnostic Tools

The following tools are necessary for accurate diagnosis of HO2S Bank 2 Sensor 2 issues:

- A scan tool capable of reading live sensor data, including oxygen sensor readings.

- A digital multimeter for checking sensor resistance and voltage.

- A vehicle repair manual specific to the vehicle make and model.

Step-by-Step Procedure

This procedure Artikels the steps to diagnose HO2S Bank 2 Sensor 2 issues.

- Initial Inspection: Visually inspect the sensor for any physical damage, such as cracks, corrosion, or loose connections. Note any obvious issues with the wiring or surrounding components. Document all observations for later reference.

- Scan Tool Data Acquisition: Connect the scan tool to the vehicle’s diagnostic port and retrieve the live sensor data for the HO2S Bank 2 Sensor 2. Note the sensor’s voltage and amperage readings across various engine operating conditions.

- Resistance Measurement: Disconnect the sensor from the vehicle. Use a multimeter to measure the resistance between the sensor’s terminals. Compare the measured resistance with the values specified in the vehicle repair manual. Significant deviations from the expected resistance values indicate a possible sensor malfunction.

- Voltage Measurement: Reconnect the sensor and measure the voltage output using the multimeter under various engine operating conditions (idle, acceleration, and steady-state). Record these values for later analysis. Refer to the repair manual for expected voltage ranges for each operating condition.

- Data Analysis: Analyze the scan tool data and voltage readings gathered during different engine operating conditions. Compare these readings to the expected values Artikeld in the repair manual. Significant deviations may indicate a problem with the sensor, wiring, or control module.

- Troubleshooting Based on Data: Based on the collected data, troubleshoot potential sensor failures. If the sensor resistance is significantly different from the specifications, it likely indicates a faulty sensor. If the voltage readings fluctuate excessively or fall outside the expected range, this could point to wiring issues or control module problems.

Typical Sensor Readings

The table below provides typical sensor readings under various engine operating conditions. These are representative values and may vary based on specific vehicle models and operating conditions.

| Engine Operating Condition | Expected Sensor Voltage (V) |

|---|---|

| Idle | 0.1-0.9 |

| Light Acceleration | 0.2-0.8 |

| Steady-State Operation | 0.3-0.7 |

| High Acceleration | 0.4-0.6 |

Repair and Replacement

The replacement of a faulty Heated Oxygen Sensor Bank 2 Sensor 2 (HO2S Bank 2 Sensor 2) requires careful attention to procedure to ensure proper functionality and avoid further complications. Incorrect replacement can lead to misdiagnosis, inefficient engine performance, and potential damage to other components. This section details the steps, tools, and potential issues involved in the repair process.Proper replacement of the HO2S Bank 2 Sensor 2 is critical for maintaining optimal engine performance and emission control.

Failure to follow the prescribed procedures can result in inaccurate readings from the oxygen sensor, leading to poor fuel efficiency, increased emissions, and potential engine damage.

Replacement Procedure

A systematic approach to replacing the HO2S Bank 2 Sensor 2 is essential to ensure the sensor is installed correctly and the integrity of the exhaust system is maintained. The following steps Artikel the procedure.

- Safety Precautions: Ensure the vehicle is securely parked on a level surface and the engine is turned off and cooled sufficiently. Disconnect the negative battery terminal to prevent accidental electrical shocks. Ensure proper ventilation in the work area.

- Access and Disassembly: Locate the HO2S Bank 2 Sensor 2. Carefully remove any protective covers or insulation to gain access to the sensor. Note the original orientation of the sensor and any securing mechanisms.

- Disconnect the Sensor: Use the appropriate socket wrench and/or tools to disconnect the electrical connector from the sensor. Handle the connector carefully to prevent damage to the wiring or the sensor. Note the position of the connector and the wiring.

- Remove the Sensor: Use the appropriate wrench or socket to loosen and remove the sensor from its mounting position. Take care to avoid damaging the exhaust system or surrounding components. If the sensor is corroded or stuck, appropriate tools may be required for removal, such as a sensor removal tool.

- Installation: Carefully install the new sensor into the mounting position. Ensure the sensor is properly aligned and secure. Use the appropriate torque specifications to tighten the mounting bolts.

- Reconnect the Sensor: Connect the electrical connector to the sensor, ensuring it is securely engaged. Double-check the connection to ensure a solid and secure connection.

- Final Checks: Reconnect the negative battery terminal. Start the engine and allow it to run for a few minutes to ensure the sensor is operating correctly. Check for any leaks or unusual noises. Perform a diagnostic check to confirm proper sensor operation.

Tools and Materials

Appropriate tools and materials are crucial for the successful replacement of the HO2S Bank 2 Sensor 2. Using incorrect tools can lead to damage to the sensor or the vehicle’s exhaust system.

| Tool/Material | Description |

|---|---|

| Socket Wrenches | Various sizes to fit the sensor mounting bolts. |

| Wrench Set | For removing and tightening various fasteners. |

| Electrical Connector Tool | To disconnect and reconnect the electrical connector. |

| New HO2S Bank 2 Sensor 2 | Ensure correct part number and specifications. |

| Gloves | Protect hands from contaminants. |

| Safety Glasses | Protect eyes from debris. |

| Torque Wrench | For precise tightening of the sensor mounting bolts. |

| Diagnostic Scanner | To verify sensor functionality after installation. |

Potential Complications

Several complications may arise during the replacement process. These include corroded sensor threads, stuck sensor, damaged wiring, or difficulty in disconnecting the sensor. If the sensor is severely corroded, it might require specialized tools or techniques for removal.

Performance Impacts

A malfunctioning Heated Oxygen Sensor Bank 2 Sensor 2 (HO2S Bank 2 Sensor 2) significantly impacts engine performance, fuel efficiency, and emissions. The sensor’s role in precisely measuring the oxygen content of the exhaust stream is critical for the engine control module (ECM) to adjust fuel delivery. Deviations from the sensor’s accurate readings can lead to substantial performance decrements.The HO2S Bank 2 Sensor 2, like other oxygen sensors, provides real-time feedback to the ECM.

This feedback allows the ECM to fine-tune the air-fuel mixture for optimal combustion. A faulty sensor introduces inaccuracies in this feedback loop, resulting in improper fuel delivery, ultimately affecting engine performance and fuel economy. This, in turn, can lead to adverse impacts on emissions.

Effects on Engine Performance

A malfunctioning HO2S Bank 2 Sensor 2 can lead to a variety of performance issues. The engine may exhibit a rough idle, stumble under acceleration, or experience decreased power output. These symptoms stem from the ECM’s inability to maintain an optimal air-fuel ratio due to the sensor’s inaccurate readings. For example, a sensor consistently reporting a lean mixture might cause the engine to run hotter than intended, reducing power and efficiency.

Impact on Fuel Efficiency

The sensor’s critical function in maintaining the optimal air-fuel ratio directly affects fuel efficiency. A faulty HO2S Bank 2 Sensor 2 can cause the engine to consume more fuel than necessary to achieve a given power output. This inefficiency is evident in reduced fuel economy. For instance, a consistently rich mixture, reported by a faulty sensor, will result in excessive fuel consumption, decreasing the overall fuel efficiency.

Impact on Emissions

A malfunctioning sensor disrupts the precise control of the air-fuel ratio, impacting emissions. If the mixture is too rich, unburnt hydrocarbons are released, increasing emissions of volatile organic compounds (VOCs). A lean mixture, on the other hand, can lead to incomplete combustion, resulting in higher levels of carbon monoxide (CO) and particulate matter. This can potentially violate emission standards and cause environmental concerns.

Comparison with a Properly Functioning Sensor

A properly functioning HO2S Bank 2 Sensor 2 allows the ECM to maintain a precise air-fuel ratio, optimizing combustion efficiency. This results in smoother engine operation, increased fuel economy, and reduced emissions. Conversely, a faulty sensor disrupts this process, leading to compromised performance, decreased fuel economy, and elevated emissions. The difference in performance between a functioning and malfunctioning sensor is readily noticeable, affecting drivability and environmental impact.

Correlation between Sensor Readings and Engine Performance Metrics

| Sensor Reading | Engine Performance Metric | Description |

|---|---|---|

| Lean Mixture (Sensor consistently reading high O2 levels) | Reduced Power, Rough Idle, Decreased Fuel Efficiency | The engine is not receiving enough fuel for the amount of air intake. This results in less power, an unstable idle, and a decrease in fuel economy. |

| Rich Mixture (Sensor consistently reading low O2 levels) | Rough Idle, Stuttering Acceleration, Increased Fuel Consumption | The engine is receiving too much fuel relative to the air intake. This results in a rough idle, stumbling during acceleration, and an increase in fuel consumption. |

| Stable, Accurate Readings | Smooth Operation, Optimal Fuel Efficiency, Reduced Emissions | The engine receives the correct air-fuel ratio, leading to smooth operation, optimal fuel economy, and reduced emissions. |

Environmental Considerations

Malfunctioning heated oxygen sensors (HO2S) can contribute significantly to vehicle emissions, impacting air quality and the environment. Proper understanding of the environmental consequences of sensor failure, along with responsible disposal practices, is crucial for minimizing negative impacts. This section explores the environmental ramifications of a faulty HO2S Bank 2 Sensor 2 and Artikels best practices for minimizing its impact.A malfunctioning HO2S Bank 2 Sensor 2 can disrupt the engine’s ability to regulate emissions effectively.

This disruption leads to increased emissions of pollutants such as hydrocarbons, carbon monoxide, and nitrogen oxides, directly affecting air quality in surrounding areas. The extent of the impact depends on factors such as the severity of the malfunction, the vehicle’s usage patterns, and local environmental conditions.

Environmental Impact of Malfunctioning HO2S

A malfunctioning HO2S Bank 2 Sensor 2 can lead to an improper air-fuel mixture in the engine, causing a reduction in efficiency and an increase in exhaust emissions. This inefficient combustion process releases more harmful pollutants into the atmosphere. The resulting elevated emissions can contribute to smog formation, acid rain, and other environmental problems.

Effect on Emissions and Air Quality

The improper air-fuel ratio resulting from a malfunctioning sensor leads to increased emissions of pollutants. Higher levels of hydrocarbons, carbon monoxide, and nitrogen oxides are released into the atmosphere, contributing to smog formation and negatively impacting air quality. This can have detrimental effects on human health, particularly in populated areas. Reduced fuel efficiency due to the sensor malfunction also leads to a higher carbon footprint from increased fuel consumption.

Proper Disposal of Old Sensors

Proper disposal of old heated oxygen sensors is crucial to prevent environmental contamination. Sensors contain materials like precious metals and other potentially hazardous substances. These materials can leach into the environment if not disposed of correctly. Recycling centers and auto parts stores often have designated drop-off points for old sensors, ensuring proper handling and recycling of these materials.

Proper disposal practices prevent the spread of these materials into landfills and waterways.

Importance of Recycled Materials in Sensor Manufacturing

Using recycled materials in the manufacturing process for heated oxygen sensors reduces the environmental impact of sensor production. Recycling precious metals and other materials used in sensor construction conserves natural resources and lowers the overall carbon footprint associated with manufacturing. This approach aligns with sustainable practices, reducing the demand for raw materials and minimizing waste generation.

Environmental Regulations Concerning Vehicle Emissions

“Vehicle emissions standards are established to control the release of pollutants into the atmosphere, thereby protecting public health and the environment. These standards vary across regions and jurisdictions and are periodically updated to reflect advancements in technology and environmental concerns. Failure to comply with these standards can result in significant penalties and legal repercussions.”

Sensor Specifications

Precise specification of Heated Oxygen Sensor Bank 2 Sensor 2 (HO2S Bank 2 Sensor 2) is critical for proper vehicle operation and diagnostics. Variations in sensor characteristics across manufacturers and models necessitate careful consideration to ensure compatibility and accurate performance evaluation.Accurate specification data, including voltage, resistance, and frequency response, is crucial for proper operation and diagnostics. Mismatched sensors can lead to inaccurate readings, affecting engine performance and emissions.

Voltage Output Specifications

Understanding the voltage output characteristics of the HO2S Bank 2 Sensor 2 is essential for interpreting its operating status. The sensor’s output voltage varies in response to changes in the exhaust gas oxygen concentration. This dynamic response allows for precise monitoring of the catalytic converter’s effectiveness. Different manufacturers may utilize different voltage ranges for their sensors, often calibrated to specific operating parameters.

Resistance Characteristics

The resistance of the sensor is an important parameter, providing insight into the sensor’s health and performance. Initial resistance values are critical to ensuring the sensor is functional upon installation. Resistance changes over time, influenced by factors like temperature and operational wear, and can provide early warning indicators of potential sensor failure.

Frequency Response

The sensor’s frequency response describes how quickly it can detect and respond to fluctuations in oxygen concentration. A rapid response time is crucial for maintaining optimal engine performance. Faster frequency responses are typically desired, enabling the engine control unit (ECU) to make timely adjustments to maintain fuel-air ratios. Variations in frequency response across different sensor models can impact the overall performance of the vehicle’s emission control system.

Comparative Analysis Across Manufacturers

Significant variations in specifications can exist between different manufacturers and models. For example, some sensors might exhibit a higher voltage output at a specific oxygen concentration compared to others. Careful comparison of specifications, including resistance ranges and frequency response characteristics, is essential for ensuring compatibility with the target vehicle.

Importance of Matching the Correct Sensor

Selecting the correct sensor is paramount for accurate diagnostics and optimal engine performance. An improperly matched sensor can lead to inaccurate readings, impacting the ECU’s ability to adjust the fuel-air mixture. Consequently, this can result in reduced fuel efficiency, increased emissions, and potential engine damage.

Resistance Values and Their Significance

Resistance values are indicative of the sensor’s internal condition. A significant deviation from the expected resistance range could signal a malfunction. A higher-than-normal resistance value might suggest a sensor heating element or other internal component failure. Lower-than-normal values could indicate issues with the sensor’s circuitry or connections.

Summary of Specifications

| Sensor Type | Voltage Range (V) | Resistance Range (Ω) | Frequency Response (Hz) |

|---|---|---|---|

| Bosch 12345 | 0.1-0.9 | 100-200 | 10-50 |

| Denso 67890 | 0.2-0.8 | 150-250 | 15-60 |

| NGK 45678 | 0.15-0.75 | 120-280 | 8-45 |

Note: Values are approximate and may vary depending on specific model and operating conditions.

Maintenance Strategies

Proper maintenance of the Heated Oxygen Sensor Bank 2 Sensor 2 (HO2S Bank 2 Sensor 2) is crucial for optimal engine performance, fuel efficiency, and extended sensor lifespan. Neglecting preventative maintenance can lead to premature sensor failure, increased emissions, and potentially costly repairs. This section Artikels key strategies for maintaining the sensor’s functionality.

Preventative Maintenance Strategies

Regular preventative maintenance is vital for the longevity of the HO2S Bank 2 Sensor 2. This includes routine inspections and cleaning, ensuring proper wiring connections, and maintaining optimal engine oil quality. These proactive steps minimize the risk of sensor failure and associated issues.

Importance of Regular Inspection and Cleaning

Regular visual inspection of the HO2S Bank 2 Sensor 2 is essential. This involves checking for signs of physical damage, such as cracks, corrosion, or loose connections. Accumulation of debris, such as carbon deposits or dirt, can hinder the sensor’s performance. Cleaning the sensor in accordance with manufacturer specifications is crucial for maintaining its accuracy. Failure to address these issues can lead to inaccurate readings, compromised oxygen sensing, and potentially reduced engine efficiency.

Checking Wiring and Connections

Maintaining the integrity of the wiring and connections associated with the HO2S Bank 2 Sensor 2 is paramount. Inspect all wiring for any signs of damage, such as fraying, cuts, or exposed wires. Ensure all connections are secure and properly tightened. Loose or damaged wiring can result in erratic sensor readings and hinder the signal transmission to the engine control module (ECM).

This can lead to inaccurate fuel delivery, reduced power output, and potentially even engine misfires.

- Visually inspect wiring for damage, ensuring no exposed wires or breaks are present. Damaged wiring can lead to electrical shorts and signal loss.

- Verify all wiring connectors are firmly secured. Loose connections can lead to intermittent sensor readings.

- Use appropriate tools and techniques for handling wiring and connectors to avoid accidental damage.

- Check the wiring harness for any signs of corrosion or moisture accumulation. Corrosion can compromise the electrical conductivity and lead to sensor malfunctions.

Role of Engine Oil Quality in Sensor Longevity

Engine oil quality significantly impacts the longevity of the HO2S Bank 2 Sensor 2. High-quality oil, with proper viscosity and additive packages, minimizes friction and wear within the engine’s components, including the sensor’s mounting location. Contaminated or low-quality oil can lead to premature wear, resulting in sensor degradation and reduced sensor life. The presence of contaminants can also affect the sensor’s operation and contribute to premature failure.

Yo, my heated oxygen sensor bank 2 sensor 2 is acting up again. It’s kinda messing with my car’s performance, you know? Like, totally affecting the whole engine thing. Maybe checking out Midland Real Estate Hong Kong midland real estate hong kong for some serious property investment could help pay for the repairs, though. Nah, just kidding.

Still gotta figure out this sensor issue first, tho.

Suggested Maintenance Schedule

The following table Artikels a suggested maintenance schedule for the HO2S Bank 2 Sensor 2. Adherence to this schedule is recommended to proactively address potential issues and maximize sensor lifespan.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Every 5,000 miles or monthly | Inspect for physical damage, debris accumulation, and corrosion. |

| Wiring and Connection Check | Every 10,000 miles or quarterly | Ensure all connections are secure and wiring is intact. |

| Engine Oil Change | As per manufacturer recommendations | Use high-quality oil to minimize wear and tear on the sensor. |

| Sensor Cleaning (if necessary) | As needed or as per manufacturer recommendations | Clean the sensor with appropriate cleaning agents. |

End of Discussion

So, there you have it—a comprehensive look at the heated oxygen sensor bank 2 sensor 2. Understanding its function, potential problems, and troubleshooting steps is crucial for maintaining your car’s performance and fuel efficiency. By following this guide, you can confidently tackle any issues related to this vital component, ensuring your engine runs smoothly and efficiently. Now go forth and conquer those engine problems!

FAQ Guide

What are the typical symptoms of a failing heated oxygen sensor bank 2 sensor 2?

Check engine light, rough idling, poor fuel economy, and unusual emissions are common indicators. A bad sensor can also lead to decreased power and acceleration.

How often should I replace this sensor?

There’s no set replacement schedule. It depends on the sensor’s condition, the driving environment, and the car’s overall maintenance history. However, regular inspections and monitoring of the sensor’s readings are essential.

What are some common causes of heated oxygen sensor bank 2 sensor 2 failure?

Faulty wiring, sensor degradation, or damage from extreme temperatures are common culprits. Also, improper installation or poor engine maintenance practices can contribute to sensor issues.

Can I clean a heated oxygen sensor instead of replacing it?

Sometimes, a cleaning might be enough, but it’s often not recommended. A failing sensor might have internal damage that a cleaning won’t fix. Replacing the sensor is usually the better approach for long-term reliability.